Production processes are all activities related to the production of products. These include the gradual completion or creation of the expected product in accordance with the design or process assumptions.

Types of production

The production of products is linked to a value chain that includes supply, technological processes, transport and storage. Types of production can be differentiated by nature, location or volume.

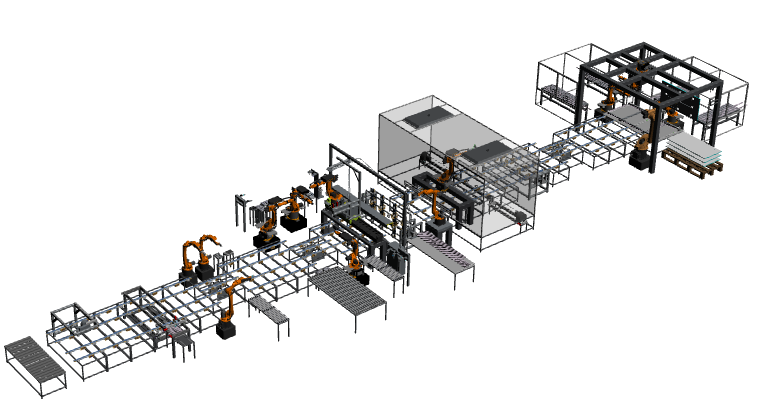

Production lines

The organization of processes is arranged sequentially,where subsequent stages follow each other, finally giving the finished product. Production lines can be manual, semi-automatic or fully automated and robotic. Highly efficient lines are usually geared towards the production of one or several different products. Efficiency comes from the speed of individual processes, and the transformation of tools to different products affects volumes. Lines that are adapted to the production of different products must be equipped with additional equipment that will allow them to handle products that differ, for example, in size.

Production is flexible

An example of such a solution is a line for the installation of lighting lamps. On a conveyor with several different stations, you can put one of the many types of positioning trolleys, which are adapted to specific lamp sizes. In this way, production is flexible and more products can be added – all you have to do is design and manufacture a new typeofproduct.

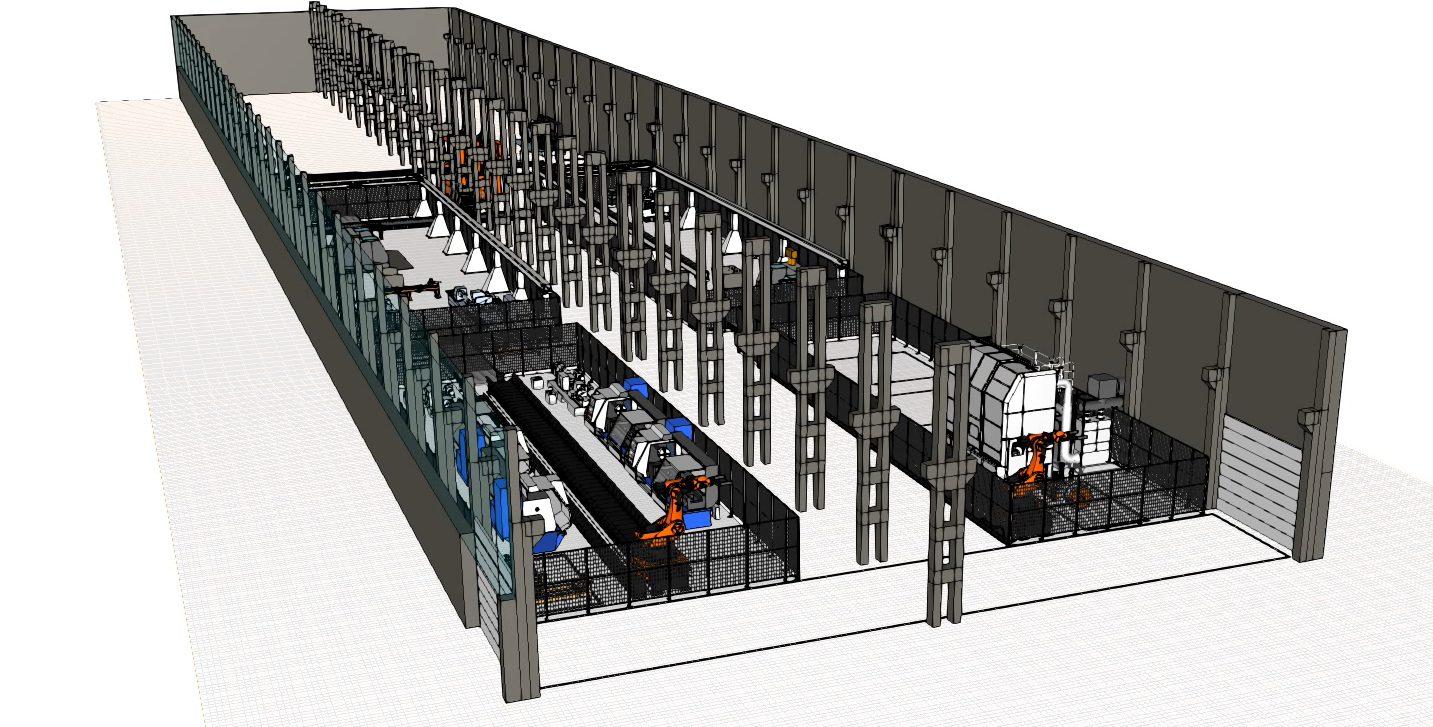

Nest production

Nest production is a more flexible variant of a traditional production line. Individual workstations or process stations are not permanently bound by the flow of the product. This means that we can produce different types and types of products by changing the order of the stations. This type of production is possible if some technological processes do not have to follow each other.

Hi-runner

Our nest production concept has been applied to a factory in the furniture industry. We have unified all robotic stations, so they can be rearranged according to your needs. The most common products are manufactured on thehi-runnerline. On the other hand, all the others can be produced flexibly by making sockets in individual technological lines.

Diffuse generation

Distributed production proved itself in the era of the pandemic, when various industries suffered from lockdown or lack of raw materials. This type of manufacturing is not tied to a specific place. Based on 3D models, production can be subcontracted depending on the availability of human and material resources. This is where 3D printing and, for example, laser cutting work great. Distributed production allows you to save your own resources and make the customer independent of suppliers. New technologies help to produce more and faster, but in this case the emphasis should be on the security of our data – i.e. digital libraries and data transfer, for example.

Production processes

Production processes

– mechanical – completing and assembling, twisting, assembly, cleaning, labeling

– chemical – gluing, dispensing liquids and gaskets, UV curing, painting

– permanent joining of elements – welding, soldering

– machining – CNC, grinding

– testing – mechanical,pneumatic, electrical, EOL

– natural – resulting from the natural action of the forces of nature – drying, cooling, etc.

Production processes – preparation of raw materials, transport, packaging and palletizing.

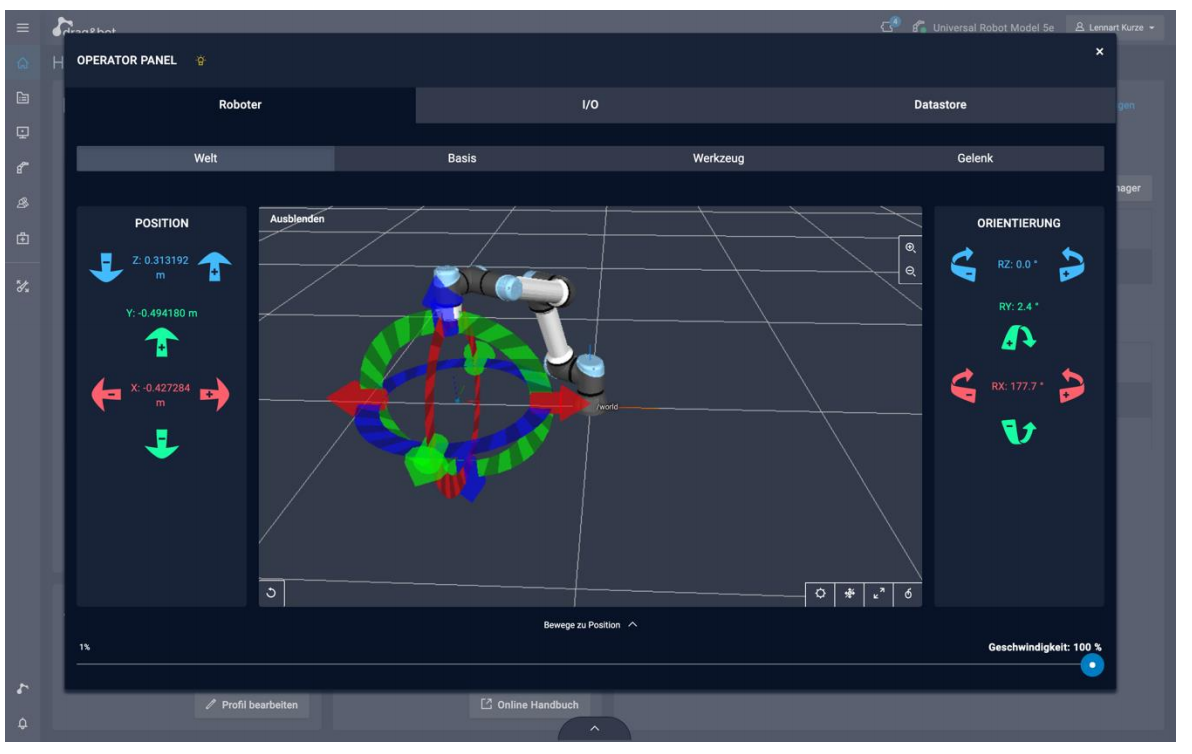

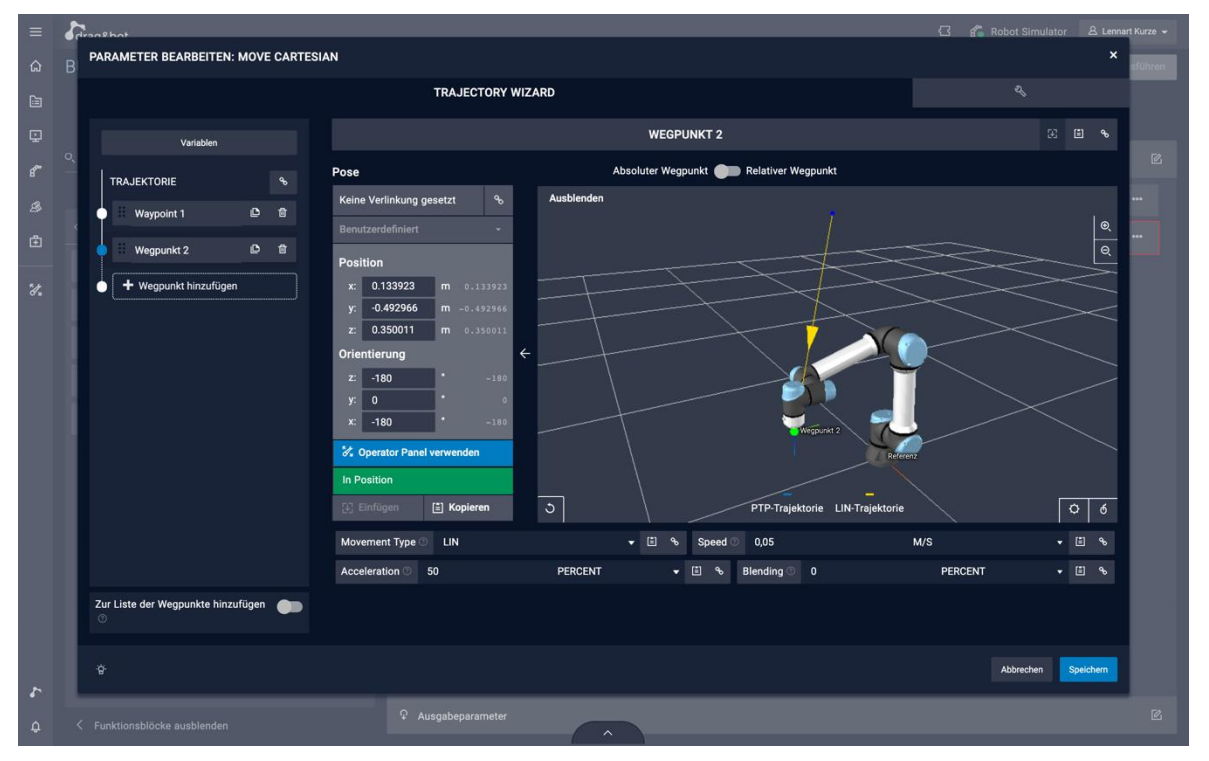

How do we do it at Alnea? We have extensive experience in implementing production processes on automatic lines. The Horus 3D vision system developed by us allows for offsetting of production processes and additionally image analysis and control, which allows you to maintain the highest standards and key performance indicators – KPIs (Key Performance Indicators).

Recent Comments