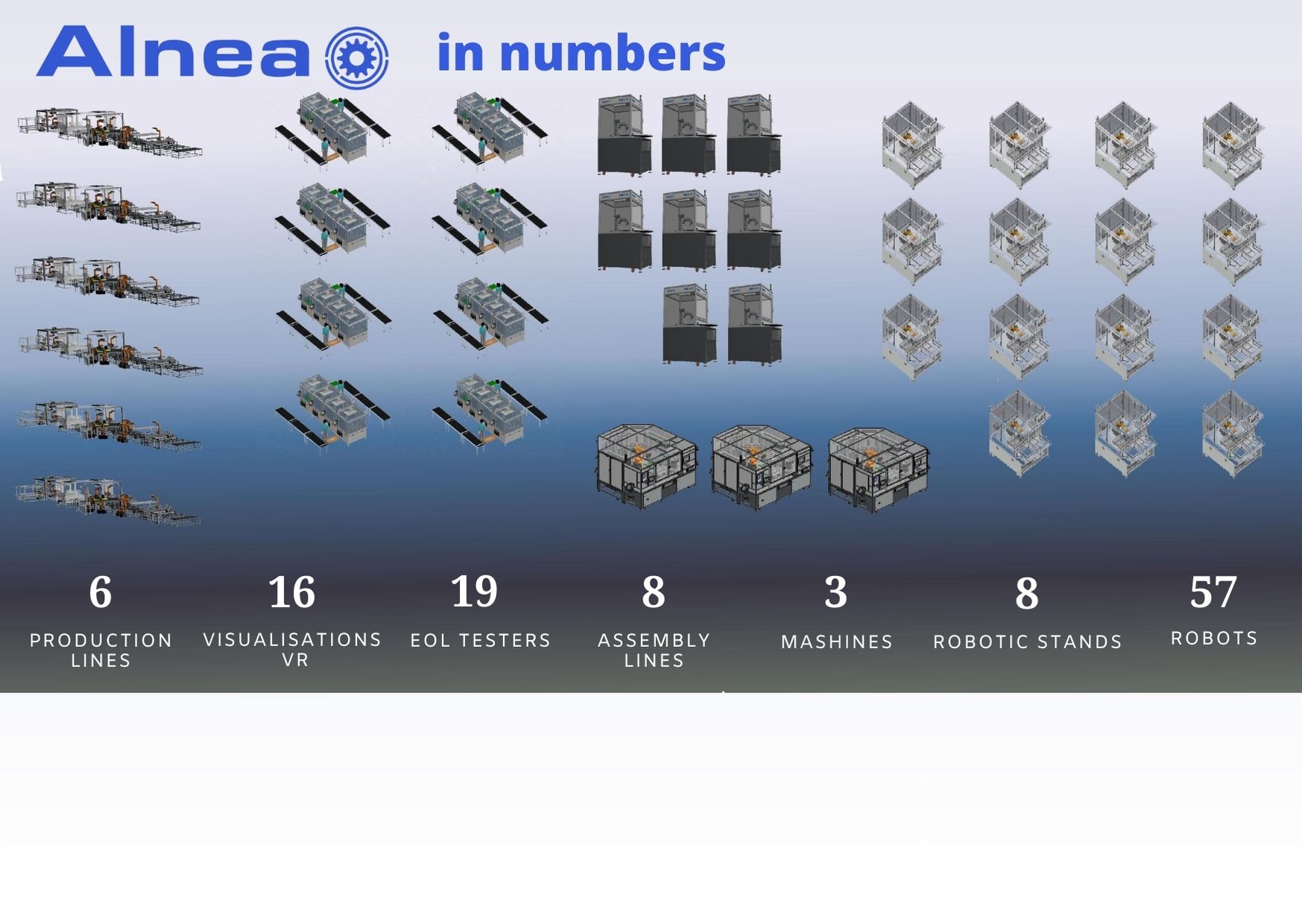

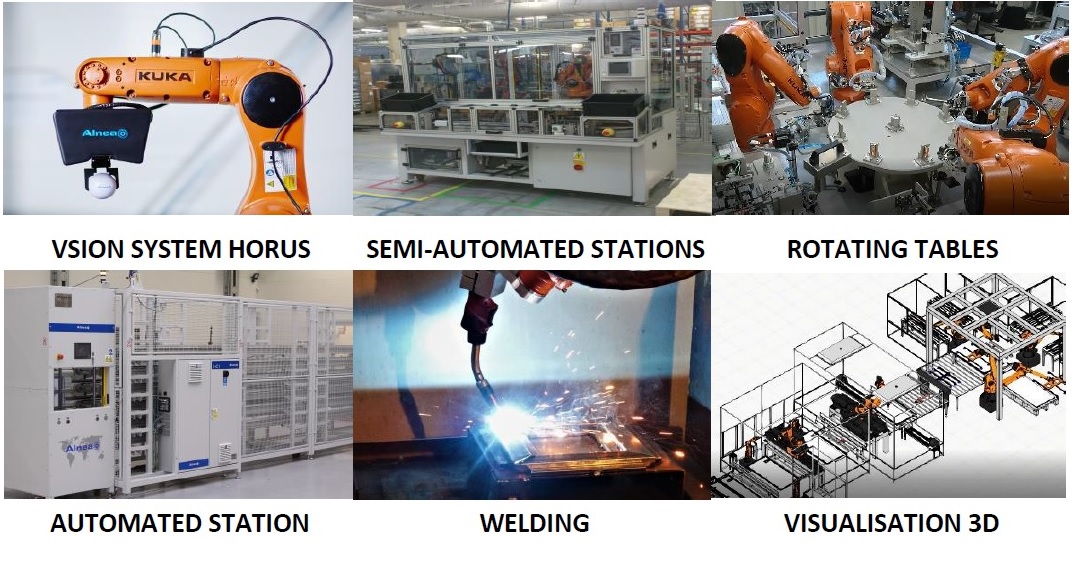

Technologies and machines gathered in Alnea allow us to develop new products, research and development, test new production solutions. We have already implemented more than one hundred different automated lines, robotic stations, production testers. We have a lot of experience in the field of automation, robotics, machine design. That’s why we decided to share our knowledge. Cycle “Tech me robot”. We have adapted the robotic room at Techroom Alnea and especially for our customers, supporters, enthusiasts and hobbyists on our You Tube channel we put short videos about different technological solutions.

Techroom - everything you want to know about AiR

Accelerating innovation development and new products in the Automationa and Robotics (AiR) market make us have huge hardware capabilities. However, there are many processes that require dedicated solutions. Techroom is a great place to test new solutions.

You can watch the first episode of Tech me in the Alnea Techroom below.

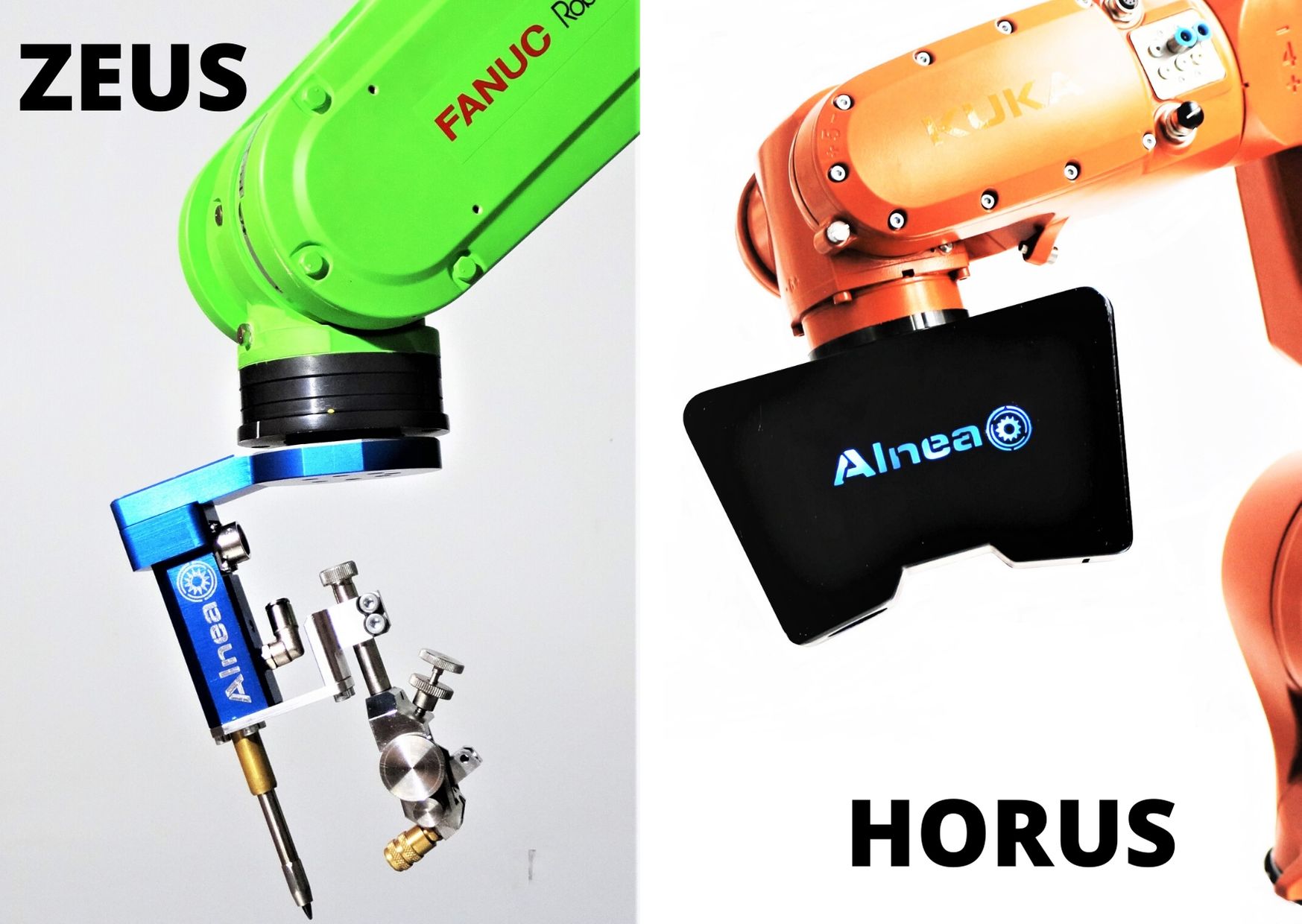

Robot soldering

Tech me is the knowledge of automation in a small pill. Recently, we have received a lot of inquiries about soldering robots. Zeus is a Alnea production controller that is ideal for robot soldering. Everything you would like to know about soldering automation can be found in the video below.

Positioning and offset

Do you know this pain when valuing deployment when a large part of the budget is absorbed by sensors, positioning and video cameras? We went through it too. That’s why we’ve created our own system that replaces hardware. Positioning and offset in one device mounted to the robot arm – this is our Horus, of course.

And about our video system episode 3 Tech me.

.

Instead of webinars

We recommend the Tech me series. Instead of hour-long webinars, you can watch interesting facts from our Techroom while waiting for the coffee water to boil … Don’t forget to subscribe to our YT channel. Thanks to this, our latest videos will not be missed! Do not forget to subscribe our YT channel!

.

Recent Comments