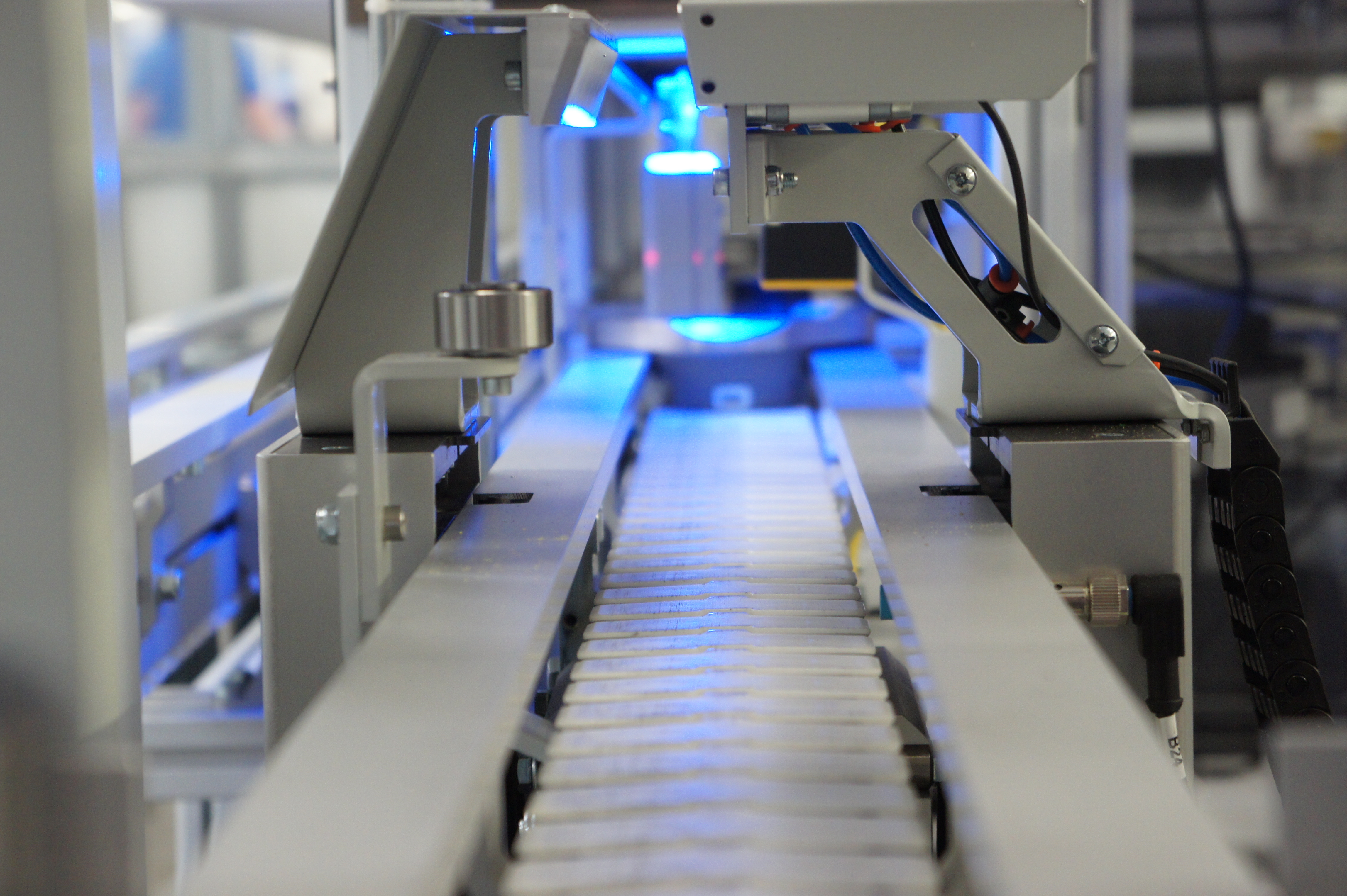

We have made a project for a optical fiber production company. The manual test station was intended to help the operator to difficultly pass the correct marking and position of the fiber optics in the sockets. We have prepared the position for three different types of products – thanks to which the return on investment was shorter than expected. The production tester designed by us ensured optimization and ergonomics of work and allowed for the scalability of the project.

Our testers are designed to be simple and operator-friendly. The test station is equipped with an HMI touch screen, thanks to which the operator chooses the right model. The prepared ribbon is laid out in the darkroom, and the other end is then pluged into the power socket. The closing of the darkroom is verified by the induction sensor because the quality of the test depends on the lack of external light.

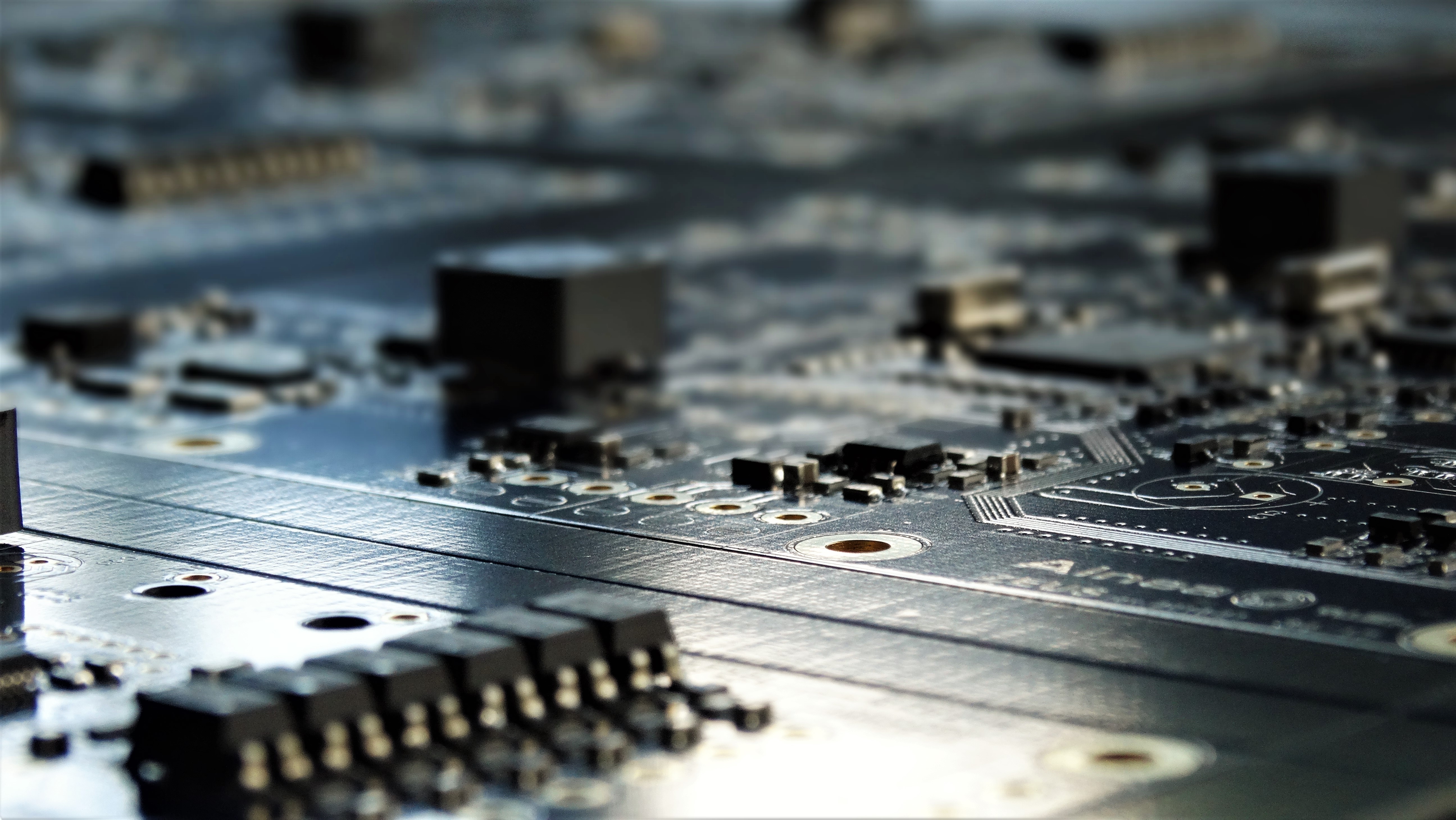

The video sensor controls the order in which the fiber ribbon LEDs light up, allowing the operator to guide the product step-by-step through the testing process. Subsequent ribbons in the fixture A are postponed to fixture B in the correct order detected by the video system. The PLC management system, in turn, generates labels which ensures our quality.

The biggest challenge of the project was the high standards of the process, which had to take place in a complete darkroom, and then further steps should be done flawlessly. We know how important it is to maintain quality with a small number of NOKs. Our production tester was able to implement quickly, and a satisfied customer ordered another 5 testing stations.

If you are interested in purchasing production testers – contact us. We will make analyses, design and perform a production tester for you. We have experience in building electrical, electronic, vision system controll, pressure, leak and other testers.

Recent Comments