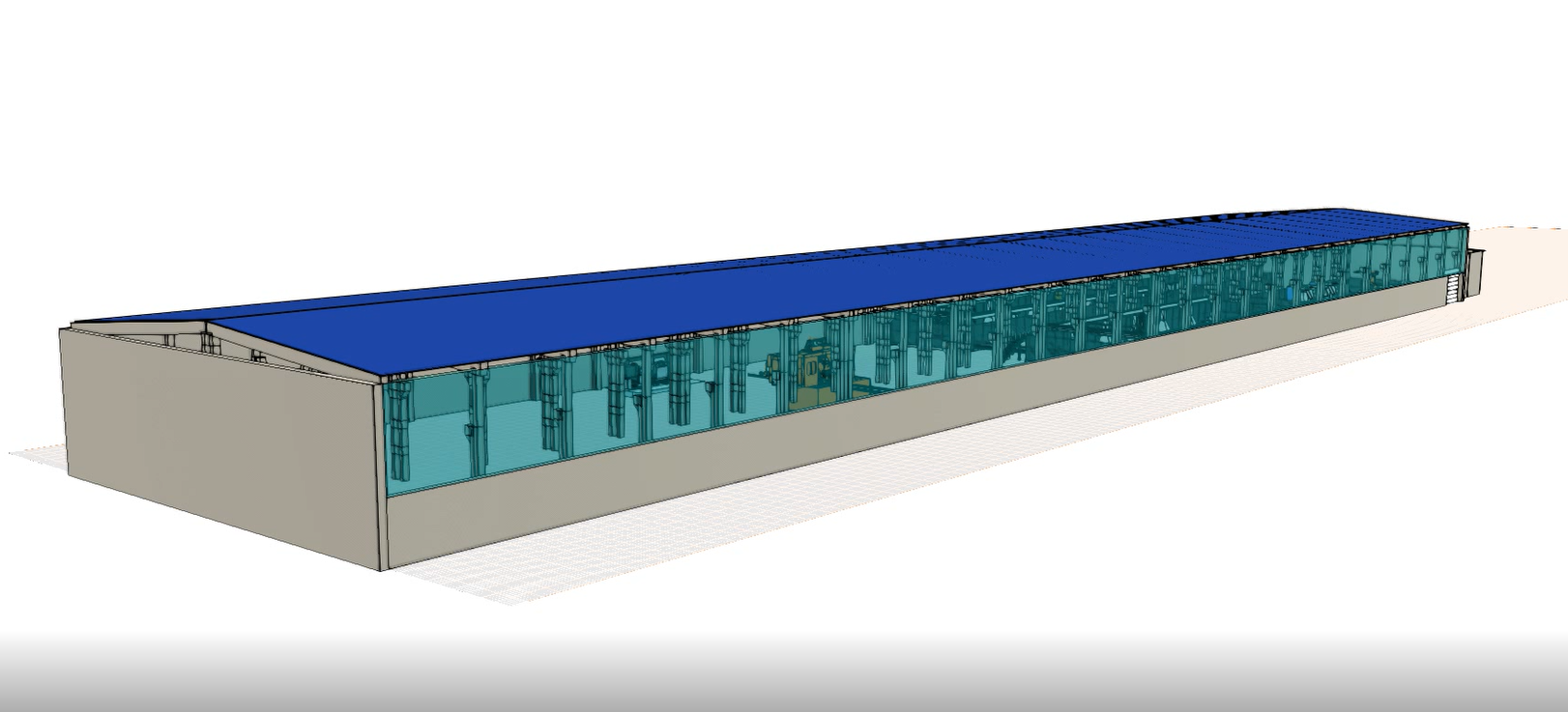

How to transform the old hall into a new production space. Drawings of designers, however, do not reflect the nature of the place and its possibilities. That is why the company director invited us to cooperate.

From the beginning…

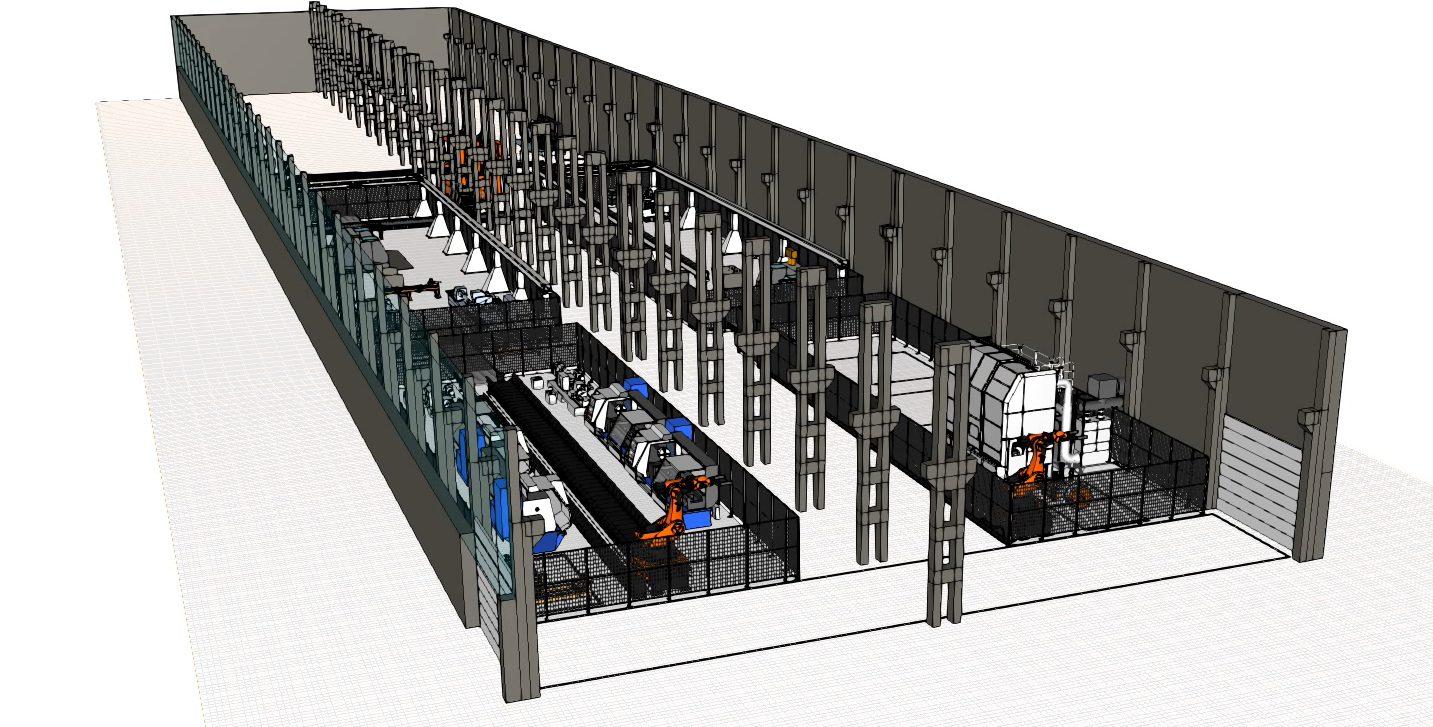

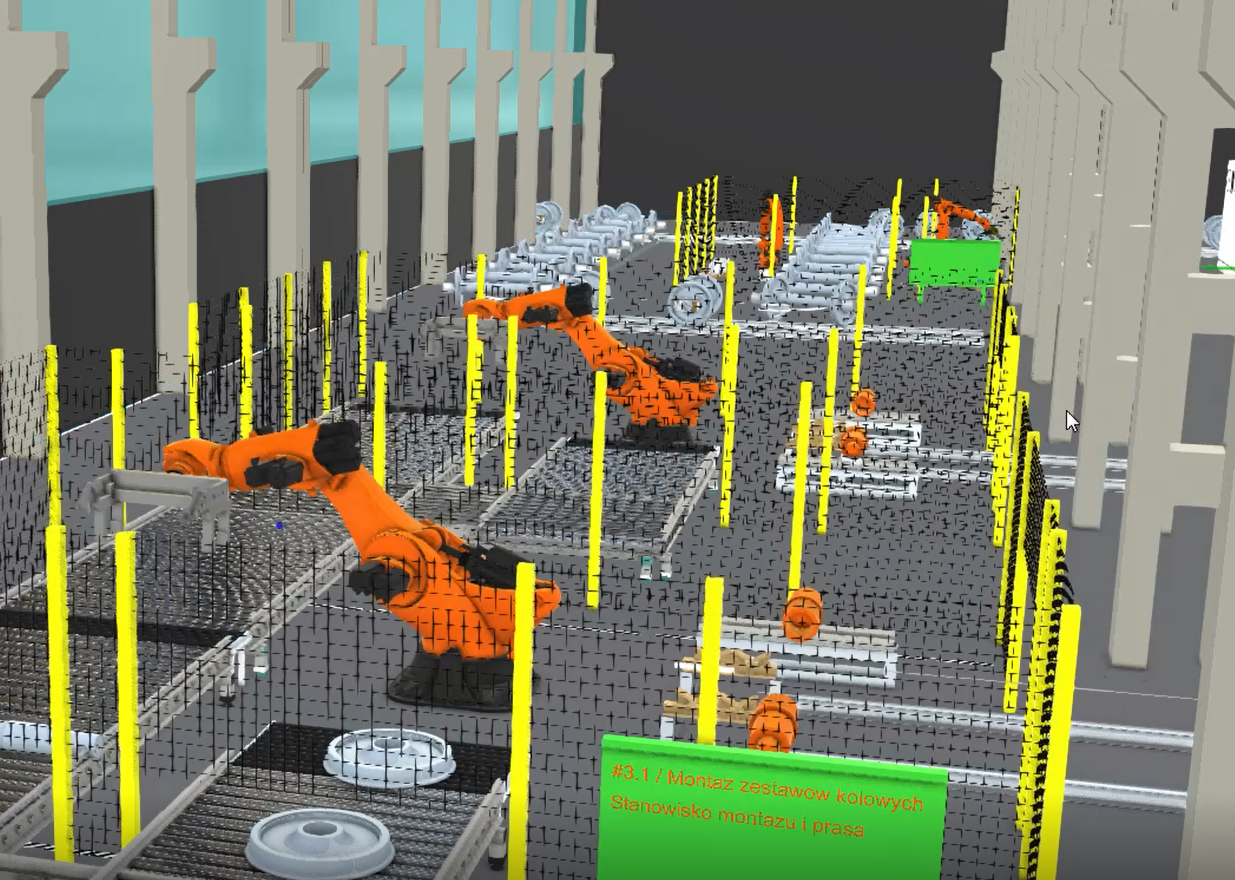

We sent two employees to the factory, whose task was to know the customer’s needs and the characteristics of the place. We made photographic documentation, took dimensions and detailed information about machines and devices that would be in the new hall. Then in a few weeks we made a static 3D mockup in Visual Components taking into account the order of production processes. It took us an additional month to add dynamics.

New reality

The intelligent factory, although it did not yet exist, was available in VR glasses. Anyone willing could enter the digital world and look at the new hall, working production machines and robots transporting components. Visualization allows you to assess the pros and cons of the designed factory and significantly affects the decision-making process. It also has an additional plus – it helps to find investors.

One service - two products

As part of the consulting service, in addition to visualization in virtual reality, we also made a promotional film. The whole is a great solution in terms of a rational approach to investment. It allows you to correct errors before the implementation stage and assess the strengths and weaknesses of the implementation. Adopting the right business model is the basis for the transformation towards Industry 4.0.

Recent Comments