Manufacturing companies are now facing increasing demands on the speed, quality and customization of the production of goods and goods. The last few years indicate an increasing need for changes and development of Polish companies. Integrators are getting more and more inquiries about production lines, which means that automation and robotization of production processes is playing an increasingly important role.

Production processes

Production processes are all activities that affect the production of products. They cover the entire value chain – transport, storage, material flows and direct actions on the raw materials, components and details that make up our final product. An important element are also technological processes related to, for example, soldering, gluing, welding, cooling, i.e. in general physico-chemical phenomena to which the product or its elements are subjected.

Types of production lines

The pioneer of production lines is considered to be the American tycoon Henry Ford, who more than a hundred years ago organized production processes in one sequence. Although, in fact, the very departure from the manufactory forced similar solutions in production companies. Although the lines were created, they now cover all industries and thanks to them most of the goods available on the market are mass-produced.

Manual lines

Manual lines are an organized sequence of processes in which all actions are performed by operators. An example would be, for example, a packaging line. At the conveyor belt on both sides there are employees performing on the koela activities – laying cardboard boxes, inserting furniture, spacers, screws and finally close the lid and palletize the finished package. Such a line can be efficient, requires an efficient flow of details and a large organization of employees who are basically irreplaceable in it.

Semi-automatic lines

Semi-automatic lines are equipped with a conveyor system and equipment that helps with assembly or other processes. Such a semi-automatic line can be a production line of lamp assembly. Thepalletsbetween the individualstationsare slowly replenished by operators thanks to automatic screwdrivers, testers, etc.

Semi-automatic lines can also have robotic sections, but between them there is always an operator station that performs some of the tasks independently

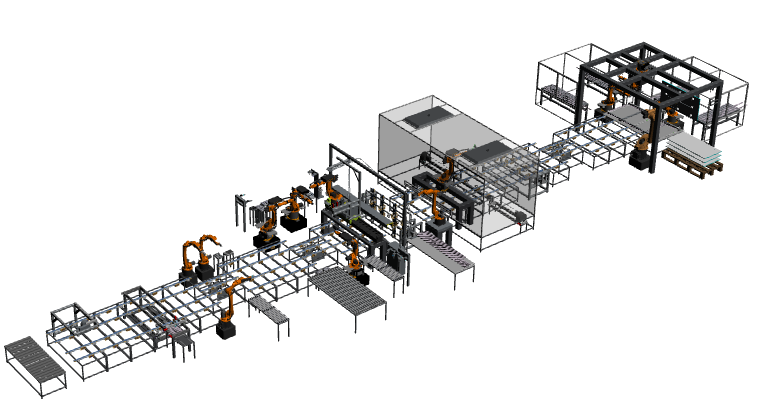

Robotic lines, automatic lines

Automatic lines are a string of automatic stations that perform a programmed sequence of actions one by one. The operator only added components, received products and watches over the correctness of processes. Yes! With automatic lines, a human is also needed. Robotic lines are advanced manufacturing centers that, although quite expensive to buy, allow you to maintain quality and stabilize production.

Assembly stations, test benches

Sometimes we don’t need a production line. All you need is, for example, an assembly station or a test stand. With uncomplicated applications, a properly designed human-operated station is not only more efficient, but also cheaper.

We build production lines

At Alnea, we have many years of experience in designing and building production lines, robotic lines, testers and assembly stations. We come to the customer, get to know his needs and requirements, and then we construct the entire machine from scratch. We have competence in the field of line construction and we recommend ourselves for cooperation. Here you can see what we have managed to create in 10 years.

Recent Comments