Modern production is primarily the digital transformation of companies and the automation of production processes. Today’s market is very demanding and difficult. In addition, the economy has still not recovered from the 2020 crisis, and now the war has reorganized value chains.

Digital Transformation

The digital transformation that Polish companies have started requires a reorganization of the approach to plans and budgets.

How to start automating production processes

Many companies are already implementing their transformation strategy. But how to start automating production processes? Preferably from an audit and a good plan. At Alnea, we know how to reorganize production – we come to the customer, take measurements, talk about the needs, possibilities and limitations of the production plant.

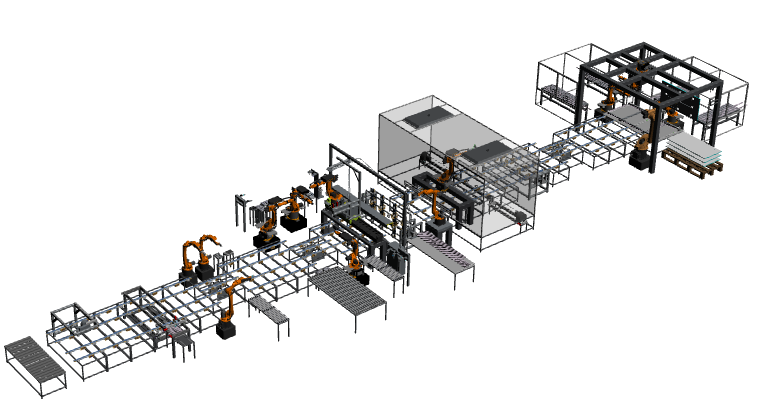

We design machines

We have been designing machines for industry for over 10 years. We started from automotive creating lines for the production of valves. We built assembly lines and robotic soldering stations. In 2021, we implemented a refubrishment line with a total length of 400m.

The eye for a robot

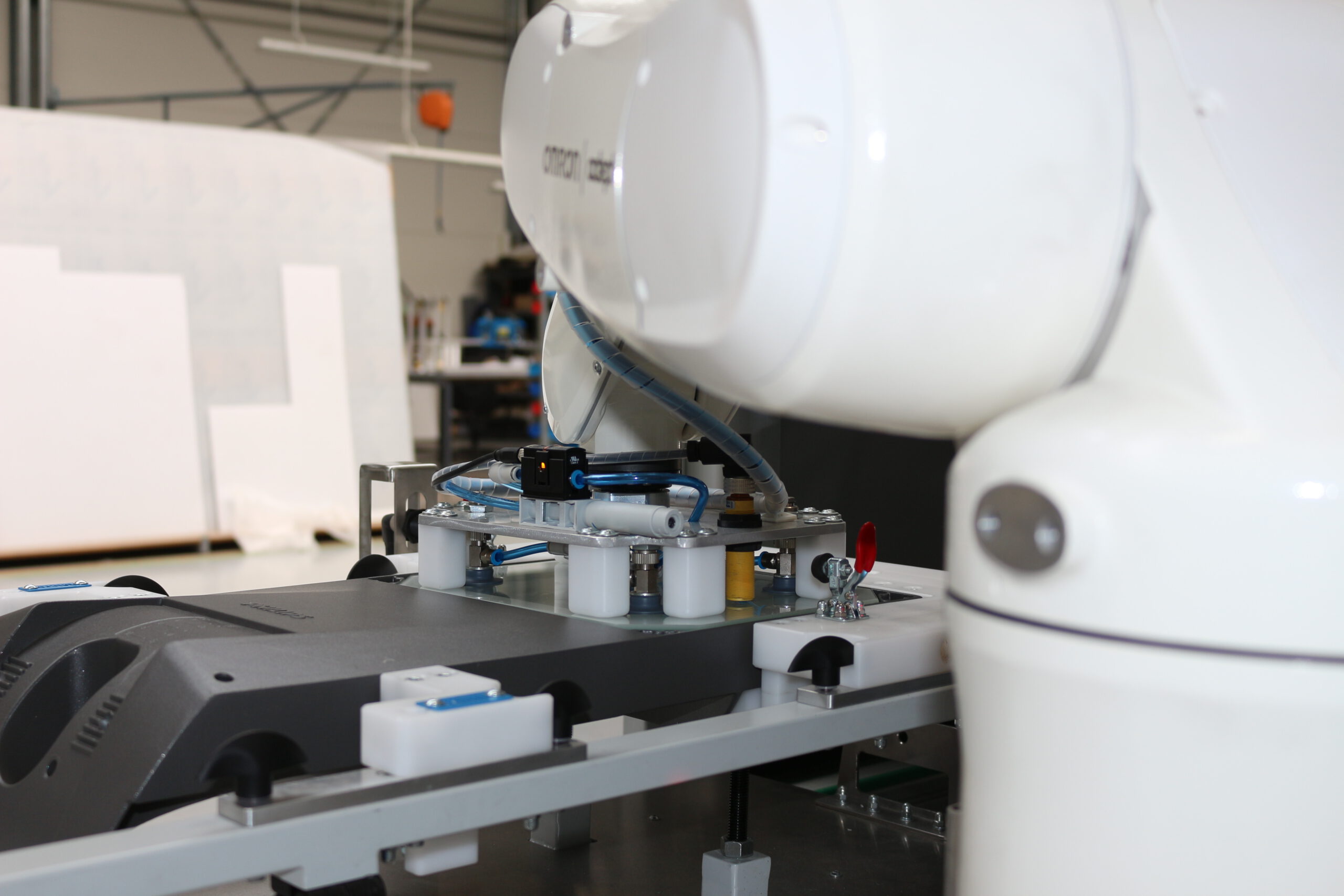

Based on our experience, we have built an eye for a robot. We noticed what a problem is the positioning of elements on robotic lines. Sensors, vision systems, positioners are not only expensive, but also their integration takes a long time. Horus – an eye for a robot – i.e. a 3D vision system is a support for production processes at the highest level.

Cost-effective production

Cost-effective production is primarily flexible, tailored to the needs of the market and ergonomic. We know how to create machines, we design solutions ourselves. An example would be a packing station. Horus mounted on a KUKA robot and matched algorithms are able to pack different components into one package with a single tool, which we have developed together at Schmalz.

Do you want to automate production?

Contact us – we will design a solution for you!

Also during the AiR Conference, we present awards to the most talented students of technical schools.

Also during the AiR Conference, we present awards to the most talented students of technical schools.

Recent Comments