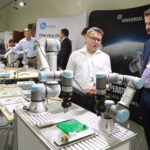

Robotized assembly line for D – profiler frames or die cast housings with PCBs with use of an automatic screwdriver and solder elements in place with use of Alnea’s Zeus Soldering Set and Horus Vision System 3d Positioning For Robot .

Elements’ transport inside and between line’s stations, screwing and soldering processes are executed by three 6 – axis robots. Line is equipped with Balluff safety systems and a safety cages, preventing interference of outside conditions or a third party.

.

Suited for client

The line is equipped with two types of dedicated box magazines. Both types have adjustable width and depth to accommodate various components.

Robot picks die cast from the box magazine and moves it under thermal paste dispenser to put the paste on the designated spots.

Three robots – complex assemblye

VEKL0005 line consists of two stations:

1) storage and preparation of components equipped with robot KUKA KR6 R900-2

2) screwing (KUKA KR6 R700-2) and soldering station (KUKA KR3 R540)

Die cast housing or D-profiler frame assembled with PCB in station 1 is placed on one of two fixtures integrated with linear drives by Station’s 2 manipulation robot. Elements are held in place by a set of pneumatic actuators during screwing process.

Die cast is moved into screwing position where PCB is screwed to the Die cast housing with an automatic screwdriver integrated with 6 – axis robot. The robot picks screws from an automatic feeder.

.

Collaboration of robots

After screwing process is finished, elements are moved into soldering position where connectors’ pins are soldered to the PCB. Soldering process is executed by station’s second 6-axis robot integrated with Zeus soldering equipment.

Zeus’ controller through which the soldering process can be adjusted is located in a cabinet on the front side of station’s A safety cage.

Alea Vision System - Eye for the robot

Finished product is removed from the fixture and placed in a box magazine on the storage rack in station 2 by the manipulation robot.

Components are handled by a robot equipped with a set of Festo grippers and Horus vision system.

Station’s robot scans the rack with Horus vision system to verify proper placement of box magazines and components inside them.

What does operator?

Operator’s task is to monitor the process with use of the HMI panel, refill screws through dedicated chute and place box magazines with components in proper spots on storage rack, monitor handling of components by the robot and remove box magazines with finished and NOK products.

What we can do for you?

What we can do for you? We can design and build production or assembly line. Alnea products guarantee innovative solutions and high precision of manufacturing with use of highest quality, repeatedly tested materials.

We will prepare for you an automatic, semi-automatic, robotic production line. Ask us about Horus Vision System!

write to us as soon as possible:

Recent Comments