Modernizing the production line is sometimes a big challenge. A good process analysis performed in front of an experienced integrator allows you to identify areas of change in the production process or the product itself (if possible). How to find the optimal technological solution? – you need to test several different possibilities. Here are some of our experience as an integrator in a lighting company:

Production tests

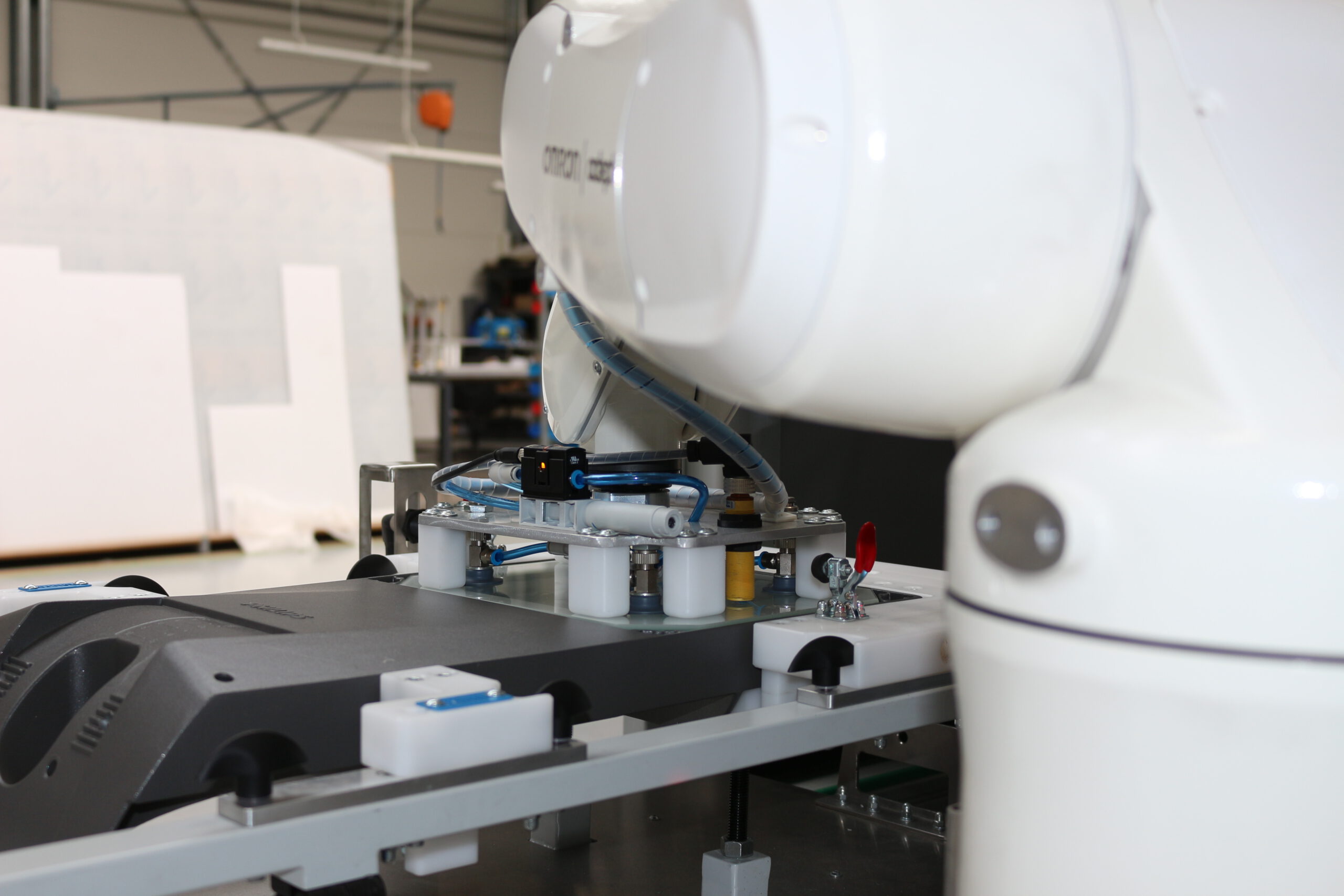

Robotic position in the assembly line. The robot took the glass and placed the lamp in the housing, and then screwed the corners withagiven accuracy.

When we did the production tests for the installation of the lamps, we had a serious problem with the spacer, which was supposed to protect the fast during transport. The robot sometimes took the glass at the same time as the paper spacer, which created additional difficulties and simply took time. We did production tests and we were still not happy with the tacktime. We took a closer look at the spacer and found that it was completely unnecessary. Fast, they were extremely scratch-resistant. So we reduced spending – for the supplier, adding paper cardboard was also problematic and we accelerated the production process.

Positioning

The robot takes the LED plate and places it in the lamp holder.

We had a big problem with the positioning of the plate – there was no element in the housing to which the robot could position the plate so that it did not move. After analyzing the design of the housing, we proposed to change the casting so that the outline of the place for the plate is consistent with its circumference. Since the customer was able to redesign the housing, we gained on the accuracy of the insert arrangement, but also reduced the installation time.

Excessive tool wear

We have designed a tool specifically for the customer to screw screws into the housing. However, after implementation, it turned out that it wears out faster than weanticipated. It turned out that the product going to the paint shop had nosecuredplaces for screws. The paint-drenched thread made it difficult to screw, destroy the tool and slow down the process. Simple solution – securing screw seats gave us savings and faster lead times..

Production testers

Why invest in production testers? According to the OEE principle, it is better to produce less and better than more with defects. Production testers allow us to reject defective products so that they do not take up space, time and components for products made correctly. This is also important because of the level of energy consumption, the waste of which costs more and more. One such danger zone is the painter’s. Incorrect painting of an element makes it sometimes impossible to correct it anymore. Testing the elements coming in and out of the painting shop – e.g. the Horus vision system – allows for significant savings. The higher the Overall Equipment Effectiveness (OEE) rate, the better the production rate. Lepiej is to produce feweer elements, but of higher quality than more with high recoil.

Online consultation

A pandemic does not save manufacturing companies. So we offered our business partners a new solution. During the maintenance period of the machine [closed plants due to COVID],owe have put ina series of online consultations along with streaming the image from the production. We were able to optimize the process and changed the program on the machine.

After the implementation of the machine and after the warranty stage, the customer often introduces a new product type and changes need to be made – this sometimes applies to a very large number of machines. A safe option is to run tests on one device and then make changes and scale the solution to the next machine.

We adjust cooperation model at the project stage to ensure investor safety. Thus, the largest tranche of payments is accepted once the entire technical project has beenestablished. We treat customers as partners so we use flexible business models.

Recent Comments