The Warsaw Industry Week is becoming a serious competition for other events of this type in Poland. The growing exhibition space and the increasing number of companies that want to present their products contribute to the continuous increase in the number of visitors.

Trade fairs also abound in various events, conferences, thematic meetings and shows. An interesting key offer was presented by the national key cluster – Metalworking Cluster. The topics were quite wide – from exploring Asian markets, clustering, or the existential question about the role of change in the modern world – here Marcin Prokop proved himself as the leader.

Automation and Robotics

We were very pleased to meet our partners of the conference Automation and Robotization of Industry – we visited the stand of KUKA, Mitsubishi, Balluff, Fanuc, Corobotics, Pepperl + Fuchs, Technology Applied. The position of the iAutomatics portal, which plays an increasingly important role in social media among automation specialists, was extremely popular.

EYE FOR THE ROBOT - HORUS

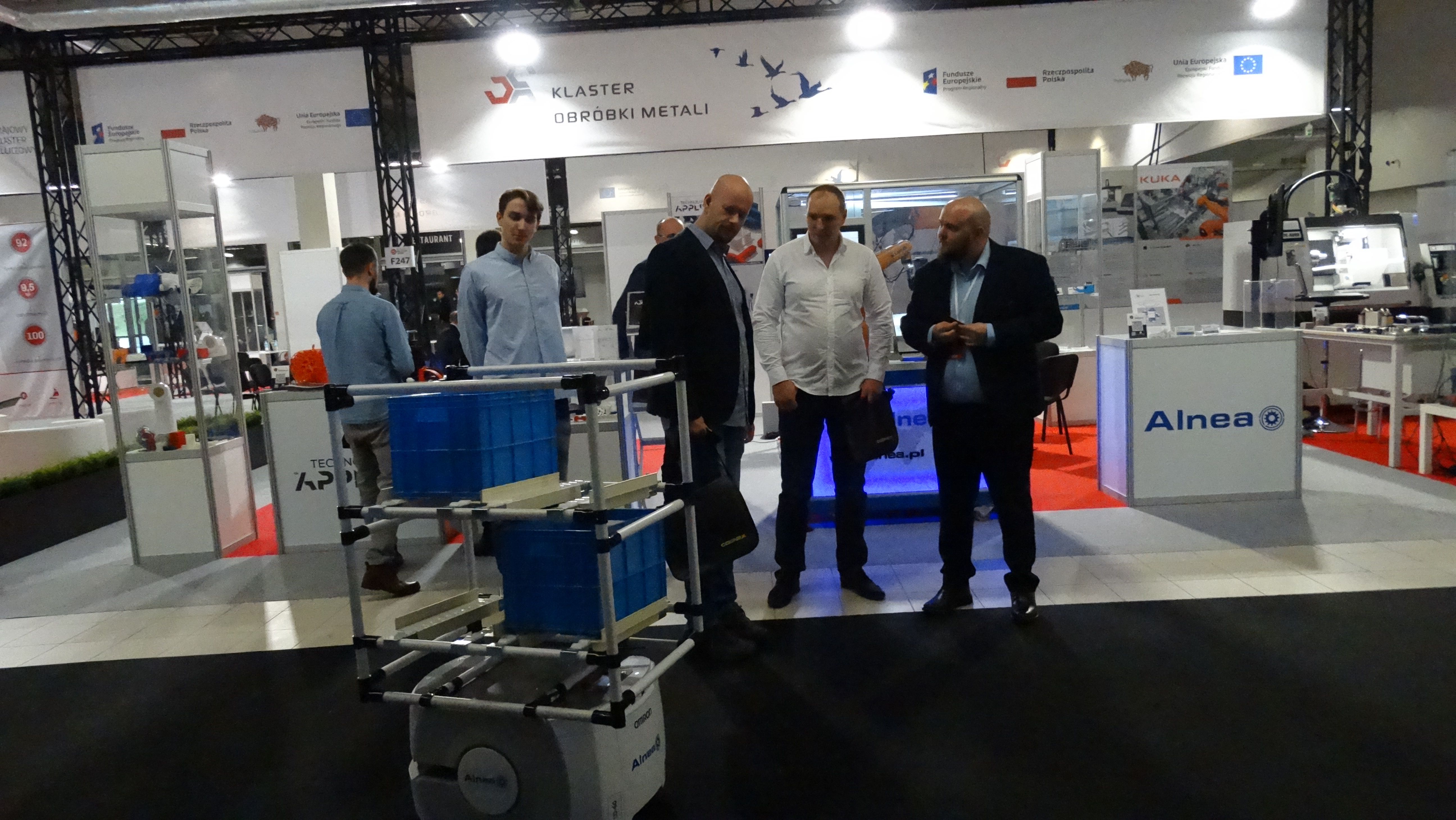

Alnea has traditionally exhibited at the exhibition space of the Metalworking Cluster. We shared the space with companies such as KUKA, Neotech, Tock, D-Tech, Technology Applied (also our partner during the conference Automation and Industry Robotization).

First of all, we presented our latest tool supporting production processes such as welding, soldering, packaging, packaging, palletizing, gluing. The 3D vision system for positioning the robot Horus is an advanced machine vision with features of artificial intelligence. Do you want to see how Horus works – we invite you to watch.

Soldering on robot – Zeus

Our patented robotic soldering package has been available on the market for several years and works in various applications – among others in the automotive sector. What we can offer our clients is a stable process with simultaneous measurement of tip temperature, adjustable amount of tin and setting of many soldering profiles.

AGV - AI in transport

Our mobile robot application Omron enjoyed enormous interest. A mobile robot with built-in artificial intelligence gathered many people mainly from production plants. The robot is equipped with a body that allows transport of 4 cuvettes to dedicated racks.

At the beginning of December, Omron is to provide a new type of robot with a higher load capacity – 250 kg, and at the beginning of the second quarter of 2020 – 1t and 1.5t. Many customers are very interested in the capabilities of these robots

At the client’s request, we also leave for tests – to sign up for such a show, fill out the form.