A very important project in the history of Alnea was the project of building a production line for the valves for the ventilation system of car seats. One of the most interesting points of the automated line was station 1, which was designed for four KUKA robots working with a rotating production wheel, where the process was kept up, that is, without stopping the wheel. This solution reduced production time by 40%. An additional benefit was the use of 4 instead of the 5 robots required by the Customer, which resulted in a lower station cost.

Another station presents the cutting process, which thanks to the use of a variable geometry stamp reduced the noise level by about 20 DB, which was one of the key requirements on the part of the customer.

The next process on the line is a soldering process based on our solution – ZEUS. The process ends with a video inspection.

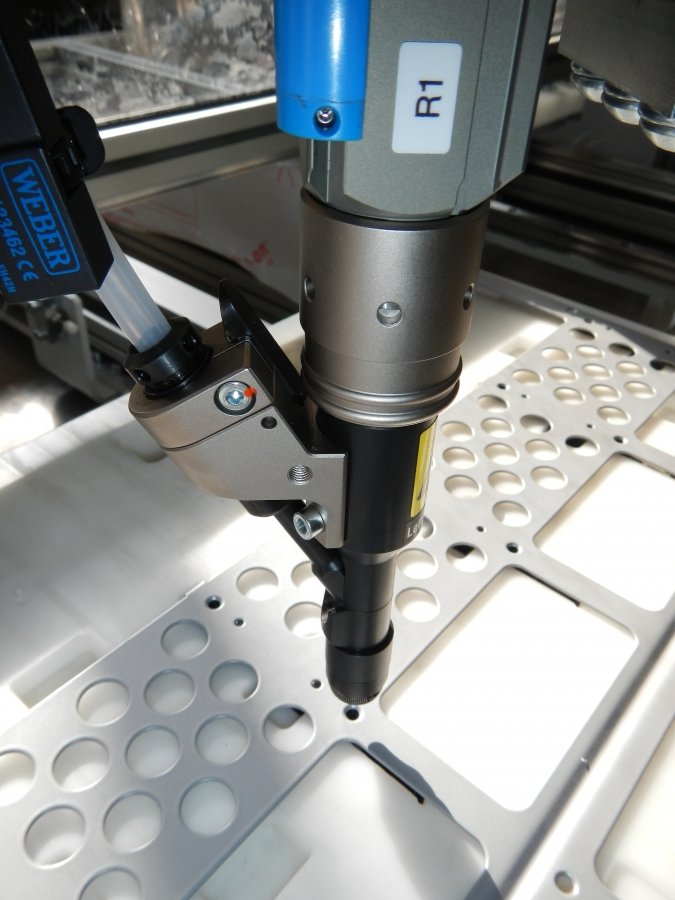

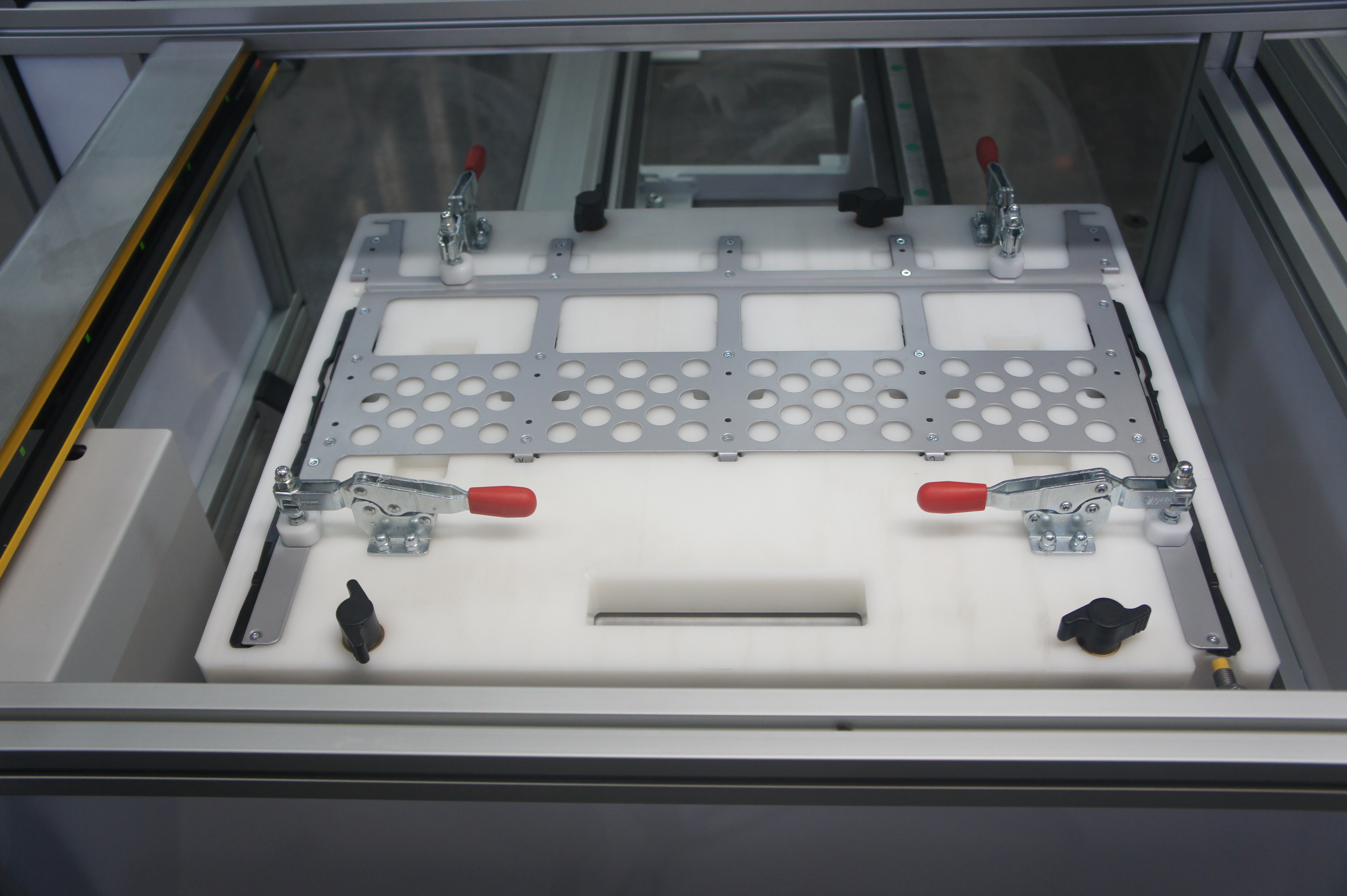

At the next station you can see the process of plasmaming or preparing the surface for the application of glue. Note that the second tool on the robot is a dispenser that precisely applies glue.

The workpiece then passes to the piston (these are components such as springs and rubber bands with a diameter of 3 mm). A robot equipped with 3 tools is responsible for the process of cutting and assembling components with each other and in the next step passes the detail for the second robot, which measures the resistance and after the process is completed, transfers the detail for further production.

A cover is mounted on the next station, which is delivered via a vibrating feeder. After the installation of the upper bodywork is completed, the part is transported again to the plasma-adhesive station. In this process, the upper body and the bottom body are connected with glue. According to the customer’s requirements, the adhesive can not be lowered into the lower body, which is why in the next production phase a UV lamp was used, which within 4 seconds hardens the applied layer of glue.

A very interesting and complicated station in this production string was a leak and flow testing station. The tests were carried out using atmospheric air and helium. I would add as a curiosity that helium leak testing was at the level of collecting individual atoms, that is, at an almost laboratory level (in the production cycle of 12 seconds). The measurement results were developed in a dedicated LabView-based application. After the tests have been completed, the detail goes to the last station, where the product marking process (OK/NOK) takes place and is armed with a so-called dumper and handed over to the operator as a ready-made valve for installation or integration into valve blocks.

Summing up 14 robots, 3 shifts, 7 days a week, a minimum of 300 products per hour, quality assurance thanks to 10 video inspection points.

Recent Comments